Convergent-Divergent nozzle solver

In this notebook I will plot the Mach number and ratios profiles along the centerline of a convergent-divergent nozzle. I will use the De_Laval_Solver.

In order to plot the ratios and Mach number along the length of a nozzle, we need to know: * the properties of the gas flowing through the nozzle. * the stagnation condition and the back pressure. * the geometry of the nozzle. At the moment, two geometries are supported: 1. CD_Conical_Nozzle: a simple conical divergent. 2. CD_TOP_Nozzle: Rao’s Thrust Optimized Parabolic contours. 3. CD_Min_Length_Nozzle: Minimum Length Nozzle built with the Method of Characteristics.

Therefore, we need to import the following modules:

[1]:

from pygasflow.nozzles import CD_TOP_Nozzle, CD_Conical_Nozzle, CD_Min_Length_Nozzle

from pygasflow.utils import Ideal_Gas, Flow_State

from pygasflow.solvers import De_Laval_Solver

import numpy as np

As an example, I’m going to consider air as the gas flowing through, and a stagnation condition at \(T_{0}=303.15K\) and \(P_{0} = 8 atm\).

[2]:

# Initialize air as the gas to use in the nozzle

gas = Ideal_Gas(287, 1.4)

# stagnation condition

upstream_state = Flow_State(

p0 = 8 * 101325,

t0 = 303.15

)

We need to define the nozzle geometry. The only non-trivial part to understand is that the transition from one region to other should be smooth, therefore: 1. throat region (connecting the convergent with divergent): * CD_TOP_Nozzle dealt automatically with this region. * CD_Conical_Nozzle: we need to define a junction radius between the convergent and divergent. * CD_Min_Length_Nozzle: by assumptio of the Method of Characteristics, the transition is a sharp corner. 2. the region

between the “combustion chamber” and convergent. For both CD_TOP_Nozzle and CD_Conical_Nozzle we need to define a junction radius.

[3]:

Ri = 0.4

Rt = 0.2

Re = 1.2

# half cone angle of the divergent

theta_c = 40

# half cone angle of the convergent

theta_N = 15

# Junction radius between the convergent and divergent

Rbt = 0.75 * Rt

# Junction radius between the "combustion chamber" and convergent

Rbc = 1.5 * Rt

# Fractional Length of the TOP nozzle with respect to a same exit

# area ratio conical nozzle with 15 deg half-cone angle.

K = 0.8

# geometry type

geom = "axisymmetric"

geom_con = CD_Conical_Nozzle(

Ri, # Inlet radius

Re, # Exit (outlet) radius

Rt, # Throat radius

Rbt, # Junction radius ratio at the throat (between the convergent and divergent)

Rbc, # Junction radius ratio between the "combustion chamber" and convergent

theta_c, # Half angle [degrees] of the convergent.

theta_N, # Half angle [degrees] of the conical divergent.

geom, # Geometry type

1000 # Number of discretization points along the total length of the nozzle

)

geom_top = CD_TOP_Nozzle(

Ri, # Inlet radius

Re, # Exit (outlet) radius

Rt, # Throat radius

Rbc, # Junction radius ratio between the "combustion chamber" and convergent

theta_c, # Half angle [degrees] of the convergent.

K, # Fractional Length of the nozzle

geom, # Geometry type

1000 # Number of discretization points along the total length of the nozzle

)

n = 15

gamma = gas.gamma

geom_moc = CD_Min_Length_Nozzle(

Ri, # Inlet radius

Re, # Exit (outlet) radius

Rt, # Throat radius

Rbt, # Junction radius ratio at the throat (between the convergent and divergent)

Rbc, # Junction radius ratio between the "combustion chamber" and convergent

theta_c, # Half angle [degrees] of the convergent.

n, # number of characteristics lines

gamma # Specific heat ratio

)

If you read through tutorial 07_Nozzles, you should have spotted an important thing: here we have define the conical and TOP nozzle to have a axisymmetric geometry, but CD_Min_Length_Nozzle only works for planar geometry. This means the areas are computed differently. We do expect some difference in the results!

At this point, I can initialize the solvers. By printing the nozzle, I will see a bunch of interesting data.

[4]:

# Initialize the nozzle

nozzle_conical = De_Laval_Solver(gas, geom_con, upstream_state)

nozzle_top = De_Laval_Solver(gas, geom_top, upstream_state)

nozzle_moc = De_Laval_Solver(gas, geom_moc, upstream_state)

print(nozzle_conical)

De Laval nozzle characteristics:

Geometry: C-D Conical Nozzle

Radius:

Ri 0.4

Re 1.2

Rt 0.2

Areas:

Ai 0.5026548245743669

Ae 4.523893421169302

At 0.12566370614359174

Lengths:

Lc 0.40213732393863305

Ld 3.7517986822069864

L 4.15393600614562

Angles:

theta_c 40

theta_N 15

Critical Quantities:

T* 252.625

P* 428225.2171235414

rho* 5.906279771438798

u* 318.5980618271241

Important Pressure Ratios:

r1 0.9998190786765753

r2 0.03863071458081746

r3 0.001112598913744237

Flow Condition: Undefined

Input state State

M 0

P 0

T 0

rho 0

P0 810600

T0 303.15

Note the Flow Condition: Undefined. This is expected, because we have not yet given in the back pressure value!

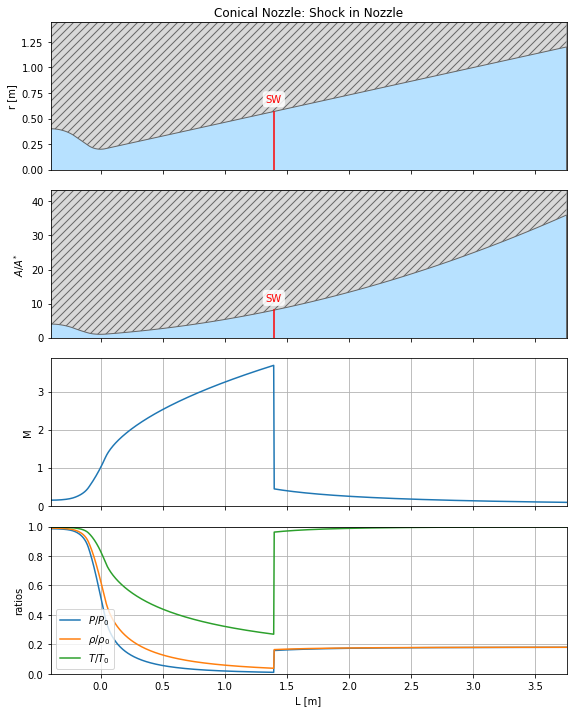

Finally, having chosen the Back to Stagnation pressure ratio, I run the computation on both nozzles and plot the results.

[5]:

Pb_P0_ratio = 0.18

nozzle_conical.plot(Pb_P0_ratio)

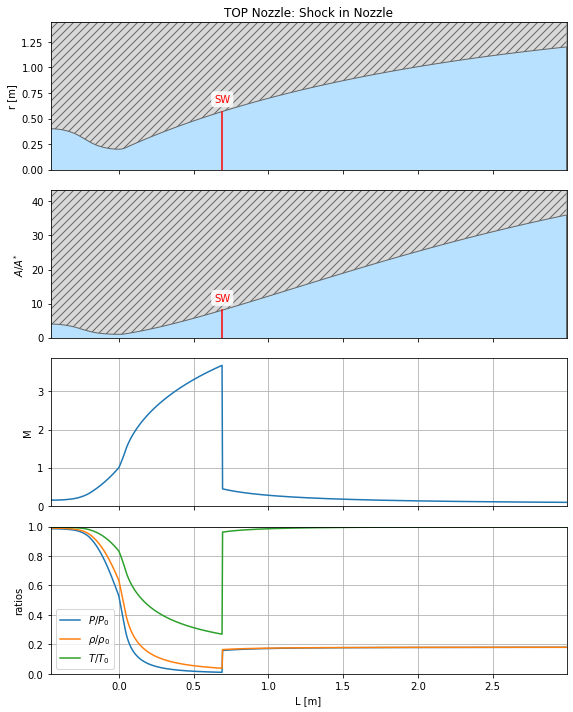

[6]:

nozzle_top.plot(Pb_P0_ratio)

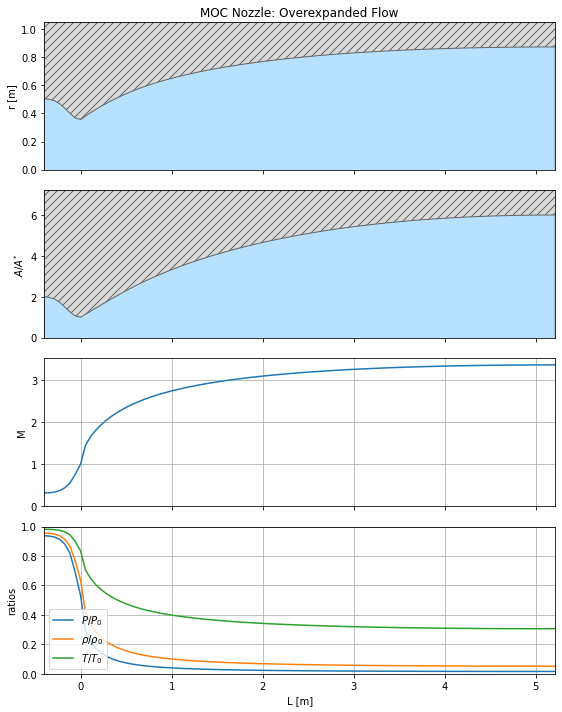

[7]:

nozzle_moc.plot(Pb_P0_ratio)

CD_Min_Length_Nozzle builds a planar geometry, the area is computed differently than CD_TOP_Nozzle and CD_Conical_Nozzle in the axisymmetric case. In the latters, the well know equation \(A = \pi r^{2}\) is used, whereas in the former \(A = 2 r\) (please, read the nozzles documentation to understand why). This leads to different area ratios, hence different Mach numbers, as we can see from the plots.We can also get an hint of it by printing the nozzle:

[8]:

print(nozzle_moc)

De Laval nozzle characteristics:

Geometry: C-D Minimum Length Nozzle

Radius:

Ri 0.4

Re 1.2

Rt 0.2

Areas:

Ai 0.8

Ae 2.4

At 0.4

Lengths:

Lc 0.40213732393863305

Ld 5.2142871958858965

L 5.6164245198245295

Angles:

theta_c 40

theta__w_max 28.186513137228662

Critical Quantities:

T* 252.625

P* 428225.2171235414

rho* 5.906279771438798

u* 318.5980618271241

Important Pressure Ratios:

r1 0.9934420158287394

r2 0.20697969674750344

r3 0.01584069664398795

Flow Condition: Overexpanded Flow

Input state State

M 0

P 0

T 0

rho 0

P0 810600

T0 303.15

[ ]: